We’re just closing up the building “envelope” on a Passive House project in Farmington. This is always an important milestone in the project because we get to test how effectively our air sealing strategy is performing while we can still get at any spots we might have missed. We’ll use a blower door to pressurize the building and walk around all its edges and junctions with a machine that creates a visible fog while folks outside watch to see if any bleeds through. [See our video of the FogTest] Once we have it sealed up we will take an official measurement at a fixed pressure (50 pascals) to assure we are exceeding the Passive House standard of 0.6 ACH50 (air changes per hour) at that pressure (which is referred to as ACH50). Building tight is one of several important techniques we employ to achieve exceptional performance.

We’re just closing up the building “envelope” on a Passive House project in Farmington. This is always an important milestone in the project because we get to test how effectively our air sealing strategy is performing while we can still get at any spots we might have missed. We’ll use a blower door to pressurize the building and walk around all its edges and junctions with a machine that creates a visible fog while folks outside watch to see if any bleeds through. [See our video of the FogTest] Once we have it sealed up we will take an official measurement at a fixed pressure (50 pascals) to assure we are exceeding the Passive House standard of 0.6 ACH50 (air changes per hour) at that pressure (which is referred to as ACH50). Building tight is one of several important techniques we employ to achieve exceptional performance.

The beauty of the Passive House method is that it is “radically simple.” It allows us to create exceptionally comfortable, durable, and healthy buildings by being miserly with the energy they we’ll depend on to maintain comfort. The way in which we construct the building enclosure (or “envelope”) is the path to success. We strive for an “energy balance” that makes the most of “free gains” to meet energy loads that have been rigorously minimized. Done successfully, very little additional energy is needed to maintain comfort. Here are the basic strategies that, when employed together, produce the desired result.

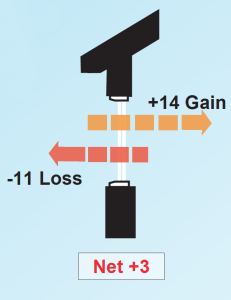

ORIENTATION & NET GAIN GLAZING

This part is simple to understand, but can be challenging to achieve. We locate high performance triple glazed windows to gain more energy than they lose on an annual basis, but without causing the building to overheat when the weather is warm. We call this “Net Gain Glazing.” This requires us to locate larger window openings across a long southerly side of the building and to be sparing in the size and location of windows on other facades. Those southern windows use glass tuned to let solar energy in which means they have a high solar heat gain coefficient (SHGC). That energy is welcome when it is colder, not so much when it is warm, so we design overhangs that shade them from summer sun. That works on the south side where the sun’s path lines up to create the desired shade, but on the east and west the sun’s angles in the morning and afternoon can’t be shaded, so there we use glass with a low SHGC to keep the building from overheating, being especially cautious to the west. On the north side there is no direct sun, so overheating is not a concern. In fact, indirect solar energy can still be captured on this side so we use the high SHGC glazing here.

This part is simple to understand, but can be challenging to achieve. We locate high performance triple glazed windows to gain more energy than they lose on an annual basis, but without causing the building to overheat when the weather is warm. We call this “Net Gain Glazing.” This requires us to locate larger window openings across a long southerly side of the building and to be sparing in the size and location of windows on other facades. Those southern windows use glass tuned to let solar energy in which means they have a high solar heat gain coefficient (SHGC). That energy is welcome when it is colder, not so much when it is warm, so we design overhangs that shade them from summer sun. That works on the south side where the sun’s path lines up to create the desired shade, but on the east and west the sun’s angles in the morning and afternoon can’t be shaded, so there we use glass with a low SHGC to keep the building from overheating, being especially cautious to the west. On the north side there is no direct sun, so overheating is not a concern. In fact, indirect solar energy can still be captured on this side so we use the high SHGC glazing here.

But the house is not just a machine to optimize. We want to create architectural interest, gather light and views, and make easy connections between inside and out. In addition, we may not have complete solar access due to existing trees, or maybe a special tree that we wouldn’t want to remove so the building sees more sun. Striking a balance between these interests and our desire to land on the positive side of the net gain glazing equation is the challenge. To create a building as efficient as a Passive House its a challenge we must understand and respond to.

THERMAL BRIDGE FREE CONSTRUCTION

When we slip a corrugated sleeve over a cup of hot coffee we are eliminating the thermal bridge caused by direct contact between our fingers and the surface of the cup. Solid building materials act like that cup without the sleeve, making a solid connection thru framing material and other building elements between inside (warm) and outside (cold). We want to use techniques that reduce the energy that is leaking from the building thru these thermal bridges to the barest minimum. The other reason we do this is to keep interior surfaces warm. Thermal bridges contribute to cold interior surfaces on which moisture can condense and cause deterioration or create the conditions that support mold growth. Warm interior surfaces also produce our sensation of comfort. When surfaces are cold they conduct heat from our bodies that make us feel cold (think of sitting next to a window on a cold day). For all these reasons we are careful to design the structure without thermal bridges, including our window frames (all those perimeter lengths add up).

A GIFT TO BE SIMPLE

Passive House performance is most directly achieved by keeping the form of the building simple and appropriately sized. A building with layer upon layer of shapes and features like bays and dormers will create conditions that produce thermal bridges, become harder to successfully air seal, and increase surface areas that transfer energy from inside to out. The challenge is to create the architectural interest that attracts us to these features thru techniques that won’t compromise performance. Instead we use adjoining roofs, porches, and other external features, establish a natural flow between the building and the land, and select exterior finishes with texture and color applied to create interest and be aesthetically satisfying. We also aim to understand how much is “enough” and don’t overbuild.

THE FANTASTIC FOUR

A high performance building is completely enclosed by four continuous barriers. Together they form a team of superheroes, each providing confident control over an essential function: weather, air, thermal, and vapor. Our choice of building materials and how they connect with each other determine how each of these barriers will successfully surround the building. We should be able to take a cut thru our building and draw an unbroken line around the perimeter along the path of each barrier. Even when we do this, there are 3D conditions that need to be recognized and resolved in the field (we use our fog test to reveal breaks in the air barrier).

A high performance building is completely enclosed by four continuous barriers. Together they form a team of superheroes, each providing confident control over an essential function: weather, air, thermal, and vapor. Our choice of building materials and how they connect with each other determine how each of these barriers will successfully surround the building. We should be able to take a cut thru our building and draw an unbroken line around the perimeter along the path of each barrier. Even when we do this, there are 3D conditions that need to be recognized and resolved in the field (we use our fog test to reveal breaks in the air barrier).

WEATHER

The weather barrier keeps out water, wind, and snow. It also excludes pests, maintains security, and insures durability. Every detail is designed to protect the building from forces that would do immediate or long term harm. The weather barrier most essentially directs water out and away, and provides the building with the ability to easily dry out without doing harm when it does get wet. The weather barrier requires durable materials, layered to direct water away, and connected to allow movement without appearing flawed. Even the most basic building has a weather barrier acting as its sentry.

AIR

Buildings have historically leaked air. Who hasn’t heard that “a building needs to breathe.” But counting on the leakiness of a building to provide fresh air for its occupants is neither effective (too much then too little, too wet or dry) or efficient (a third of the energy consumed to produce comfort can be lost to leaking air in conventional buildings). Treating energy preciously requires holding onto every drop, and air leaking is a lot of drips. Air leaking is also the way that warm moist air ends up on cold surfaces within the building structure, condensing there and causing damage or providing a home for mold or an environment that supports pests. This is why we seal the building as tightly as possible, then use controlled and balanced ventilation with heat recovery to efficiently and consistently provide fresh air. We have learned from the Europeans to employ a system of durable and long lived tapes to seal the many locations at which a building will leak. They remain flexible as the building shifts and settles over time. As we build we focus on a workflow that assures the building is tight while we can still test to see potential leak locations and fix them.

THERMAL

We can think of the building envelope as our “third skin” (clothing being the second). Improving the thermal barrier is like putting on a thicker coat; it slows the rate at which the heat inside is lost to the outside. By increasing the amount of insulation that surrounds the building on all sides, even underground, we slow the rate at which the building slowly loses heat to the outside (in a heating season). At Passive House levels of insulation we need far less energy to keep the interior warm. When we add those “free gains” from our net gain glazing and even the heat from our bodies and building equipment we will require a very small amount of additional energy to maintain comfort. This superior thermal barrier coupled with exceptional air tightness produces an interior environment in which there are no drafts, the temperature is constant throughout the space, and building surfaces are not drawing heat from our bodies and making us feel uncomfortable.

VAPOR

While our weather barrier is protecting the building from water in liquid form, we must pay attention to the ways in which water vapor moves in and out of the building. Our goal is to keep warm moist air from coming in contact with surfaces at the cooler temperatures at which they will condense and become liquid (the dew point), which could set the stage for material damage or mold growth. Water vapor transported by air is the most damaging and our rigor with air sealing is essential to eliminating that risk. Water vapor is also transported by diffusion at varying rates (permeance) and in smaller amounts (from areas of greater to lesser vapor density) and this is the risk we want to understand and manage. Because this transport can occur in both directions (in and out) we want to create conditions that either prevent its movement altogether, or assure that it will not reach a surface at the dew point and if it does, be sure we have a mechanism in place that assures it will become dry. In this sense we need a zen superhero who doesn’t so much resist the force as allow it to move through according to its nature without causing damage. We take great care to control interior moisture (to avoid elevated levels) while selecting materials in our building assemblies that are permeable (where we want flow) or impermeable (where we wish to create a barrier).

PENETRATIONS

We take great care to establish these oh so careful boundary barriers, then go and make holes in them for windows and doors that need to open and close and for pipes and wires that deliver services to the house. The pipes and wires are manageable. We take care to minimize their number and use gaskets that seal around them where they enter. We avoid large vents where possible, and insulate them when they’re necessary. That leaves the windows and doors. They are thin elements in our thick walls, and despite the windows ability to provide free gains, they challenge us to transition each barrier in, out, and around them. Much head scratching goes into how best to accomplish this and we concern ourselves not just with how it will work but creating an efficient workflow for those who install each piece of the puzzle.

GETTING IT DONE

A house is a complex assembly of many working parts, some structural, some mechanical, some functional and all hopefully creating a satisfying aesthetic whole. As we endeavor to make better buildings we are learning to pay more careful attention to the elements that, when put together smartly, create buildings that perform substantially better than what we have known and built before.